In the beverage industry, a label is more than just packaging—it’s your brand’s first impression. Skewed, flagged, or misplaced labels can lead to costly rework, compliance risks, and even brand reputation damage.

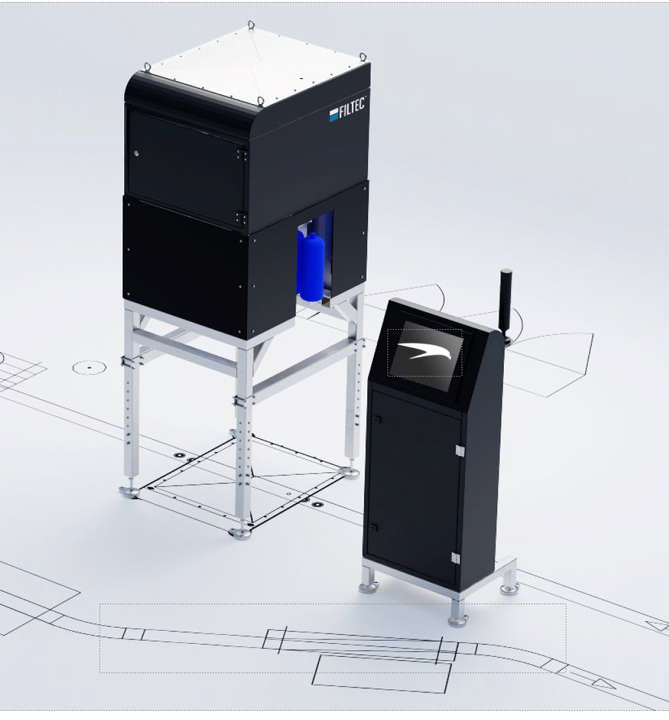

The FILTEC OmniLabel 360 is designed to eliminate these risks by delivering unmatched inspection accuracy for shrink-wrap and wrap-around labels. Built for high-speed beverage lines, it ensures that every bottle leaving your facility meets the highest standards of quality and consistency

Advanced Technology:

The OmniLabel 360 combines multi-camera vision and AI-driven inspection of glue-on and shrink sleeve labels to provide complete 360° coverage of non-oriented bottles at production speeds up to 50,000 bottles per hour.

Full Bottle Coverage: High-definition cameras capture images at 90° intervals with overlap, ensuring no blind spots and consistent results across all label types.

AI-Powered Accuracy: Deep learning algorithms adapt to variations in graphics, colors, and shrink materials—reducing false rejects.

Self-Teaching Setup: Smart calibration and auto-learning tools simplify configuration, minimizing operator training.

User-Friendly Interface: A Windows-based touchscreen HMI with intuitive graphics makes operation simple and efficient.

Built for Demanding Lines: Engineered to maintain inspection quality at ultra-high speeds without compromising precision

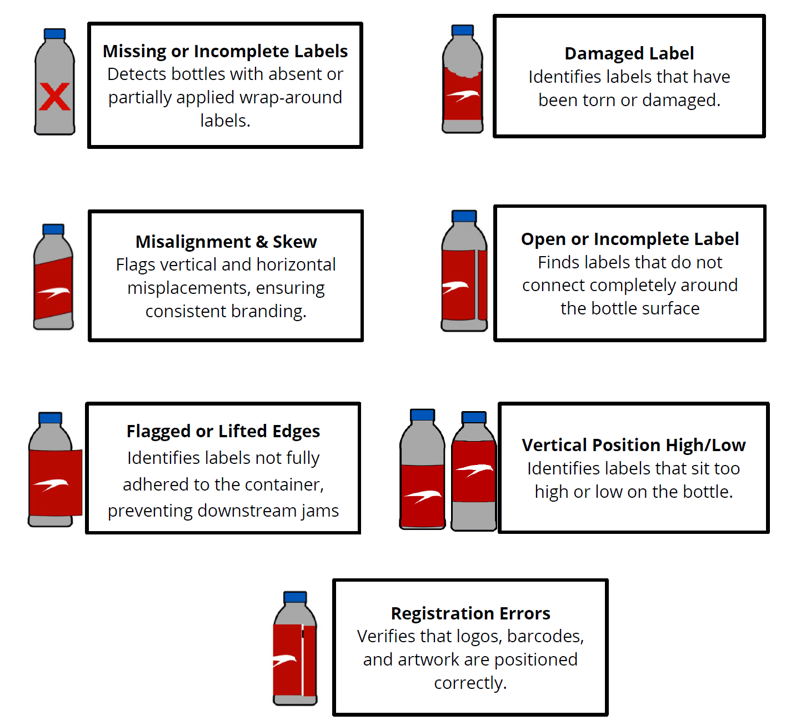

Standard applications of OmniLabel 360 include: