Coding and Code Recognition

What is coding and code recognition?

Coding and Code Recognition are essential quality assurance and traceability capabilities on modern packaging lines. Coding applies permanent or high-contrast product identification (e.g., lot, date, QR, Data Matrix).

Code recognition verifies that every mark is present, readable, accurate, and aligned—so products can be tracked through production, distribution, and return/reuse loops.

What are the benefits of Coding and Code Recognition?

Reliable coding and verification strengthens compliance, line efficiency, and brand protection—especially at high speeds and with challenging container geometries.

Key benefits:

-

-

End-to-end traceability: Enables track-and-trace readiness with accurate, machine-readable codes captured in real time.

-

-

-

Error prevention before product leaves the line: Detects missing, unreadable, or misaligned codes to reduce downstream disruptions and customer complaints.

- Higher line efficiency at scale: Solutions are designed to maintain accuracy at production speeds (example: CodeTrack DM up to 72,000 bottles per hour).

- Lower operating cost and improved sustainability: Laser marking eliminates consumables such as inks and chemicals, reducing environmental impact and ongoing maintenance.

- Better quality control: OCR/vision verification can validate codes against standards to catch incorrect lot/expiration data prior to shipment.

-

FILTEC’s Coding and Code Recognition Solutions Include:

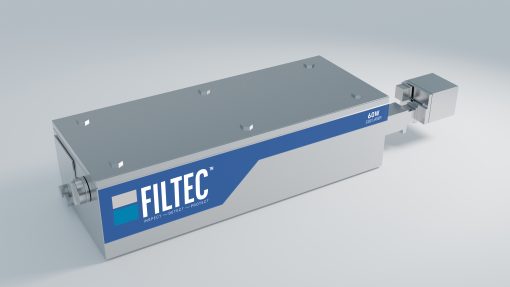

Lasetec 5 Laser Marking Solution

Permanent, high-contrast laser coding for cans, bottles, labels, and cartons—delivering reliable product identification without inks or consumables.

System Highlights:

- High-speed performance: Supports production speeds up to 120,000 containers per hour

- Consumable-free operation: Eliminates inks, solvents, and related maintenance

- Long service life: Laser source rated for up to 100,000 operating hours

- Material-specific configurations:

-

Fiber lasers for aluminum cans

-

CO₂ lasers for PET bottles, labels, and secondary packaging

- Consistent code quality: Produces durable, high-contrast marks suitable for downstream reading and traceability

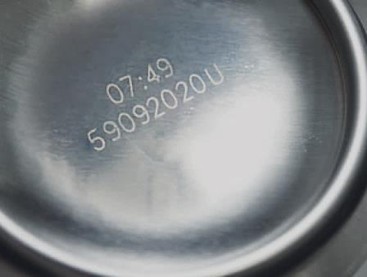

Lasetec OCR

High-speed optical character recognition (OCR) and code verification to ensure every code is present, readable, and correct before product leaves the line.

System Highlights:

-

Real-time code verification: Confirms presence, legibility, alignment, and correctness of printed or laser-marked codes

-

Supports multiple code types: Lot codes, date codes, and serialized information

-

Designed for high-speed lines: Maintains accuracy without slowing production

-

Error prevention: Detects missing or incorrect codes early to reduce rework, scrap, and recalls

-

Traceability-ready: Provides validated code data to support track-and-trace initiatives and digital QA systems

CodeTrack DM

Purpose-built Data Matrix code reading for returnable glass bottles, delivering reliable inspection on challenging neck geometries and variable glass surfaces.

System Highlights:

-

Purpose-designed for returnable and refillable glass bottles

-

360° inspection using eight high-resolution cameras at 45° intervals

-

High-speed capability: Up to 72,000 bottles per hour

-

Optimized optics and LED illumination for clear and colored glass

-

Detects missing, unreadable, or misaligned codes to support compliance and reuse programs

OMNIVISION 4 Empty Bottle Inspection

Combines empty container quality inspection with integrated QR and Data Matrix code reading to support traceability, reuse, and line efficiency.

System Highlights:

-

360° contact-free inspection using high-resolution line-scan imaging

-

Integrated QR code and Data Matrix reading on empty containers

-

Validates code presence, readability, accuracy, and orientation

-

Designed for integration with laser or inkjet coding systems after the blow molder

-

INTELLECT-enabled interface with RFID login, test bottle tracking, and touchscreen control